Safety signs and labels: common challenges

What are the most common challenges with GHS-compliant signs and labels?

Responding is Mauriah Lamia, content and social media manager, Accuform, Brooksville, FL.

With more than 43 million workers exposed to some form of chemical, nearly every company is affected by the Globally Harmonized System of Classification and Labeling of Chemicals in one way or another. Using GHS to classify and label chemicals is not an option – it’s a regulation set in place by OSHA’s Hazard Communication Standard (1910.1200).

Although we’re one year into the effective date for GHS, many people still believe it’s a complicated process. When simplified, GHS is a logical and comprehensive approach to communicating hazards. Shifting your perception could help you overcome some of the common challenges we see throughout the industry.

Challenge No. 1: Finding the information that needs to go on the GHS sign/label

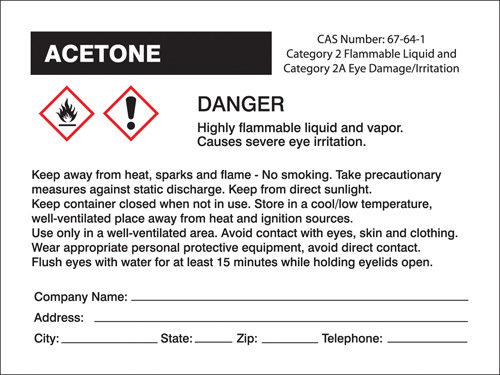

The major change to OSHA’s HCS included a revision to the appearance of the sign or label that identifies the chemical properties.

The standard requires all chemical manufacturers, distributors and importers to label hazardous chemicals by including these required elements on containers: product identifier, signal word, pictograms, hazard statements, precautionary statements and supplier identification. The information that goes onto the GHS sign or label is located on the Safety Data Sheets provided by the chemical manufacturer, distributor or importer.

Because most companies are continuing to receive SDSs, be sure to validate that the new SDS matches the chemicals on hand before replacing the material SDS. MSDS retention is the easiest path for archiving the chemical information. Additionally, make a note on the archived MSDS as to where the chemical was used and during what period.

Per OSHA 1910.1020(d)(1)(ii)(B), “Material safety data sheets and paragraph (c)(5)(iv) records concerning the identity of a substance or agent need not be retained for any specified period as long as some record of the identity (chemical name if known) of the substance or agent, where it was used, and when it was used is retained for at least thirty (30) years(1)…”

Challenge No. 2: What are the size requirements for GHS? My container is too small to fit all the required elements.

Labels, as defined in the HCS, are an appropriate group of written, printed or graphic information elements that are affixed to, printed on or attached to the immediate container of a hazardous chemical or to the outside packaging.

Because the United States has no minimum or maximum size requirements for GHS labels, it often is difficult to include all the information that needs to go onto a small label. To meet GHS requirements on small containers, you can think outside a standard label and use a tag or a custom-sized label to identify hazardous chemicals.

Challenge No. 3: I have an NFPA and/or the Department of Transportation label – so I don’t need GHS because they’re similar, right?

Some employers still are using NFPA and/or Hazardous Materials Identification System labeling on portable containers. There also are similarities between the pictograms used for GHS and those used by DOT. NFPA 704 still uses the diamond template that workers are accustomed to seeing on portable containers.

It is important to note that OSHA pictograms do not replace the diamond-shaped labels that DOT requires for the transport of chemicals, including chemical drums, chemical totes or other containers. Employers may continue to use rating systems such as NFPA diamonds or HMIS requirements for workplace labels as long as:

- They’re consistent with the requirements of HCS.

- Employees have access to the specific hazard information.

- Labels are used for internal purposes within or onsite at the facility.

Note: Once the chemical goes outside the facility, proper GHS marking prevails.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)