Workplace safety cultures

How can safety managers measure, and then impact, workplace safety cultures?

Responding is Chuck Pettinger, implementation and change manager, Predictive Solutions, Christiansburg, VA.

Answer: It is very difficult – if not impossible – to measure culture directly. Cultural surveys do measure employees’ perceptions; however, a more common and less expensive method is to measure “cultural proxies” such as near misses, closure of open items and safety inspections.

Safety inspections (or behavioral observations) provide a large quantity of these proxies through the data gathered every day, in almost every organization, from around the world. Although collected, very few organizations make use of this valuable observation intelligence. Through predictive analytics, safety professionals can use the intelligence gathered from inspections and observations, in real-time, to measure and impact their cultures. There are four simple methods to gain insight into organizational safety culture:

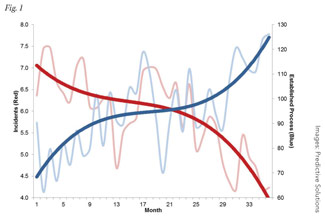

1. Look at quantity: Simply looking at the quantity of inspections can give you an idea of how much safety “activity” is taking place (Fig. 1). If people are consistently missing their observational goals, this may point to a lack of perceived value of the process or training issues. By creating a “data use plan” for leadership to provide feedback on the collected observation intelligence, the culture is strengthened by the increased value of the observations. Furthermore, if employees are aware that the data collected is being looked at and acted on, the quality of the observations will increase. Predictive analytics also have shown that as inspections increase, injuries decrease. So, does this mean organizations simply need to hire more safety professionals to do observations? Not necessarily …

1. Look at quantity: Simply looking at the quantity of inspections can give you an idea of how much safety “activity” is taking place (Fig. 1). If people are consistently missing their observational goals, this may point to a lack of perceived value of the process or training issues. By creating a “data use plan” for leadership to provide feedback on the collected observation intelligence, the culture is strengthened by the increased value of the observations. Furthermore, if employees are aware that the data collected is being looked at and acted on, the quality of the observations will increase. Predictive analytics also have shown that as inspections increase, injuries decrease. So, does this mean organizations simply need to hire more safety professionals to do observations? Not necessarily …

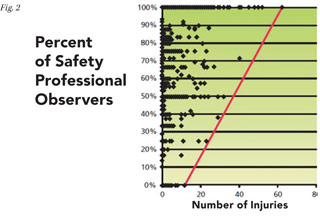

2. Look at diversity: Our research shows that an increase in inspections reduces injuries. If you look at who is participating in your inspection process, this can give insight into operational buy-in. If the safety professionals are the only ones performing observations, this may limit their role to “safety enforcer” (Fig. 2). Besides, data has proven that locations at which only safety professionals perform inspections/observations have had more injuries, whereas sites with a more diverse group of observers have experienced fewer injuries. So, to positively impact the culture, strive for more participation from operations, safety, leadership and the front-line employees in the observation process. This not only will give you a better assessment of critical safety conditions and behaviors, but also will give you more buy-in from your whole organization.

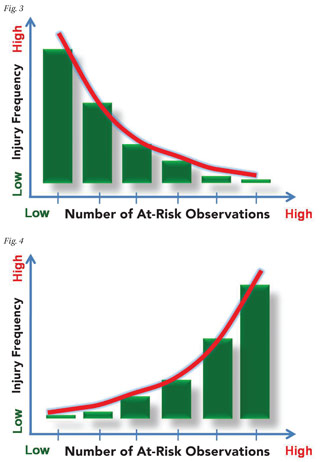

3. Look at quality: Many organizations have injuries, yet when inspections are assessed, little to no risky conditions or behaviors are documented. This is common in safety cultures that place little or no faith in leadership using their observation intelligence. Many companies believe their employees “pencil-whip” (or make up) the data on their observations (Fig. 3). This creates a cycle in which leadership does not trust that data and ignores it. Consequently, the employees feel the leadership does nothing with the data and therefore put little effort into inspection quality. To reverse this cycle, leaders need to examine the quality of the observations and be aware of the locations that turn in 100 percent safe inspections. By accepting this as a “cultural proxy” of mistrust and using the data from inspections, leadership can drastically impact the quality of the data being collected and act on the issues being identified.

3. Look at quality: Many organizations have injuries, yet when inspections are assessed, little to no risky conditions or behaviors are documented. This is common in safety cultures that place little or no faith in leadership using their observation intelligence. Many companies believe their employees “pencil-whip” (or make up) the data on their observations (Fig. 3). This creates a cycle in which leadership does not trust that data and ignores it. Consequently, the employees feel the leadership does nothing with the data and therefore put little effort into inspection quality. To reverse this cycle, leaders need to examine the quality of the observations and be aware of the locations that turn in 100 percent safe inspections. By accepting this as a “cultural proxy” of mistrust and using the data from inspections, leadership can drastically impact the quality of the data being collected and act on the issues being identified.

4. Look at frequency: Another cultural proxy comes from looking at observational data that identifies a large number of risky conditions or behaviors and has a high corresponding number of injuries. In this case, people are finding the issues, yet nothing is being done to find or fix them (Fig. 4). Again, this cultural proxy stems from not making use of the valuable observation intelligence being collected from your internal experts. Acting on and fixing issues being identified by your inspections and/or observations will create a culture of discovery and motivate employee engagement to help predict and prevent injuries.

Editor’s Note: This article represents the independent views of the author and should not be construed as National Safety Council endorsements.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)