The Importance of Tepid Water Delivery in Emergency Safety Stations

Safety Shower & Eyewash Station Recommendations

To help avoid workplace injuries, safety showers and eyewash stations are critical in facilities where personnel can be exposed to hazardous materials and chemicals. Facilities equipped with these stations must be aware of the regulatory requirements and compliance standards to install, operate and maintain these units. One of the most important factors to consider is the delivery of safe and comfortable water temperatures to employees if a shower/eyewash station is activated.

A critical concern for most employers is ensuring the prevention of high-temperature water releasing from their units and potentially scalding workers. However, low-temperature hazards are now a growing concern. A tepid water delivery system is recommended for emergency safety stations to guarantee discharge temperatures between 60° and 100° F (16-38° C), in compliance with ANSI Z358.1-2014 standards.

Supply lines or shower units installed outside are subject to solar heating, with internal water temperatures reaching 150° F (66°C) and above. Likewise, indoor units and lines may be subject to high ambient temperature conditions from process, steam or condensate lines. This over-temperature water must be purged from the system to prevent scalding.

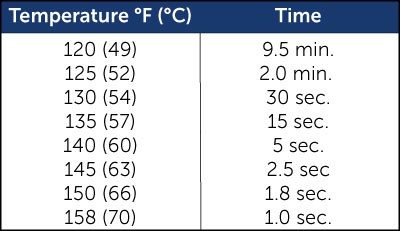

Another consideration is the relationship of time and temperature. Studies have demonstrated that there are two critical factors that determine the risk of a burn injury occurring: the temperature of the material and the length of time the skin is exposed to the temperature. For water, the following chart provides time/temperature relationships required to cause a full-thickness (third-degree) burn.

Another consideration is the relationship of time and temperature. Studies have demonstrated that there are two critical factors that determine the risk of a burn injury occurring: the temperature of the material and the length of time the skin is exposed to the temperature. For water, the following chart provides time/temperature relationships required to cause a full-thickness (third-degree) burn.

A common device used for over-temperature/scald protection by shower manufacturers and retrofitted by users is a self-operating, temperature-activated valve, such as the ThermOmegaTech® HAT/SP.

The thermostatic HAT/SP valve continually senses the water or air temperature depending on installation and will automatically bleed off the over-temperature water to prevent an individual from being scalded when they activate the safety shower or eyewash unit. The internal thermal/wax actuator operates over a 10° F (5.5° C) temperature differential, with the valve being fully closed at 95° F (35° C) and increasing to full flow if temperature reaches 105° F (40° C) or above. This purges the hot water from the system and replaces it with cooler water from the resupply line. Once the water temperature in the line is back below the scald-danger range, the valve will modulate closed again to conserve water.

In low-temperature situations, shock/hypothermia are a risk. Many facilities are now considering the effects of low water temperature in relationship to the length of time a person will shower, or the combined effects of hypothermia and shock to the victim as a result of extended exposure to cold water. (Remember: 15 minutes or more is required.)

A 1993 case recounts a power plant employee who was splashed with a hazardous solution and suffered side effects from partaking in a cold-water flush. Following plant safety procedures, the employee immediately went to the nearest shower unit after being exposed to the hazardous material, but almost immediately jumped out of the shower because of the freezing-cold water. Knowing the potential danger from burns, four fellow employees forced him back into the shower, holding him in place for the required 15-minute wash down. By the time the shower ended, he was unconscious and in shock.

Many manufacturers are addressing this concern by offering a number of variations of tempered water supply systems. These range in size and design from electric or steam water heaters to hot/cold water mixing assemblies.

ThermOmegaTech’s Tepid Water Solutions

In line with the needs within the industry, ThermOmegaTech’s Tempered Water Supply Systems are available as either a unit that mixes hot- and cold-water supply, such as the Therm-O-Mix® Station/WWM, or a unit that uses plant steam through a proprietary heat exchanger loop to indirectly heat cold water, the Therm-O-Mix® Station. Both units have redundant controls for safety and are 100% mechanical; no electrical power source is required, making them ideal for explosion-proof environments and outdoor installations. With such a small footprint, these solutions can easily be retrofitted onto existing safety fixtures to guarantee tepid water.

Implementing a tepid water delivery system into your facility’s safety shower and face/eyewash stations will reduce the risk of severe injury and improve overall workplace safety. Contact ThermOmegaTech to learn more.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)