NIOSH offers miners tips to limit dust exposure, be ergonomically sound

Washington — NIOSH has published a booklet intended to help miners learn about reducing their exposure to respirable dust in metal and nonmetal mines while lowering their risk for musculoskeletal disorders and traumatic injuries.

Noting that “multiple respirable dust sources can be present simultaneously,” the agency outlines several common exposure triggers:

- Inadequate housekeeping (e.g., buildup of material on interior structures, conveyors or transfer points)

- Lack of effective local exhaust or structure ventilation

- Lack of effective enclosure filtration

- Poor work practices (e.g., handling dusty equipment or materials and clapping hands to “clean off” gloves)

Meanwhile, NIOSH says that the five fundamental risk factors for MSDs – forceful work; poor posture; repetitive work; vibration exposure; and slip, trip and fall hazards – are often present in mine work.

“While traumatic injuries occur suddenly, both MSDs and respirable diseases tend to be the result of cumulative overexposures,” NIOSH says. “Exposures both at home and at the workplace can combine and manifest themselves in the later years of your career, depending on your exposure rates and cumulative stress.”

The agency offers various solutions for reducing dust exposures while boosting ergonomics. They include:

- When possible, use angled stairways or alternating tread stairs instead of vertical ladders to reduce the release of dust into workers’ breathing zones.

- Hose down walking surfaces and handrails to reduce dust accumulation, and practice caution until surfaces have dried.

- Consider using fully automated bagging solutions.

- Store new screens where they will be protected from collecting surface dust deposits.

- Consider using separate work stands outfitted with a local exhaust ventilation system for screen deck maintenance.

- Provide a separate, positively pressurized control room for workers.

- Spray off coiled or rolled hoses before use to reduce residual dust.

- Ensure an adequate drainage system is in place if water is used to hose down areas with accumulated dust.

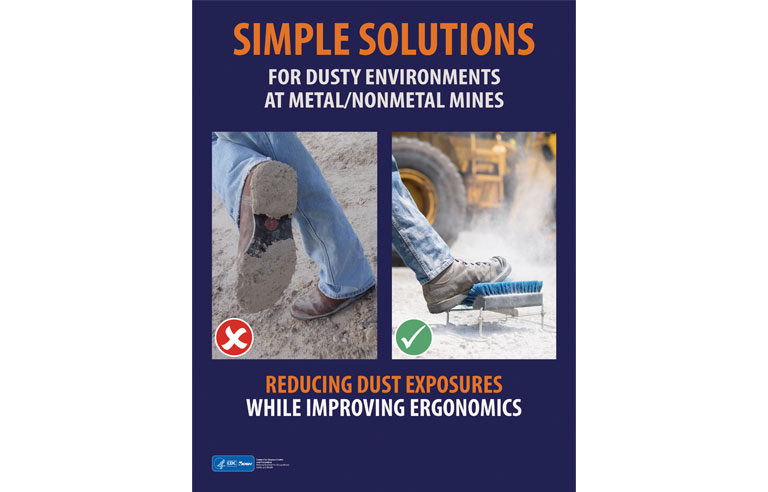

- Provide designated walkways and boot brushes at mobile equipment parking areas to help workers remove contaminants from footwear.

- Tie bag collars away from workers’ breathing zones as much as possible.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)