Reaching the limit on PELs

Calls increase for OSHA to update decades-old regulations

By Kyle W. Morrison, associate editor- Legal hurdles have hampered OSHA’s past efforts to update outdated PELs.

- Critics complain OSHA does not spend enough time or resources on health-related workplace risks.

- At a recent public meeting, several stakeholders offered ideas on moving forward, including use of the General Duty Clause.

Imagine coming across a pack of cigarettes with a warning label suggesting smoking more than 10 cigarettes a day is harmful, but fewer than that poses little to no health risk. Now imagine that assertion comes not from the cigarette manufacturer, but from a federal government agency tasked with ensuring your safety and health.

Clearly, such a warning label would be horribly out of date with current science and potentially harmful to consumers. Advocacy groups would cry foul and demand a reassessment and changes on the warning label. Something would have to be done, they might say.

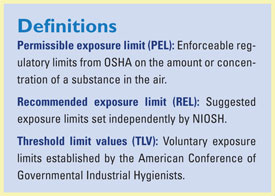

Such is the case with OSHA’s permissible exposure limits. PELs are OSHA-established regulatory limits on the amount or concentration of various substances in the air. Presently, about 500 PELs have been established, most of which have not been updated since the late 1960s. Hundreds – perhaps thousands – of other chemicals have no PEL at all. The few PELs in existence and the lack of updates have drawn the ire of many stakeholders who view chemical hazards as a major occupational health concern.

“It’s just aggravated to the point of calamity,” said Jeff Ruch, executive director of Public Employees for Environmental Responsibility, a Washington-based national alliance of local, state and federal government professionals. According to PEER, workplace exposures are the eighth leading cause of death in the United States, accounting for more than 40,000 premature deaths each year.

Further exacerbating the issue is that new research on a variety of chemicals continually brings forth findings on their toxicity at the body, organ and molecular levels, according to the American Industrial Hygiene Association in Fairfax, VA. PELs can become out of date quickly, potentially making them insufficient to protect workers and resulting in what one stakeholder called an “unacceptable gap in worker protection.”

The current process at OSHA to update PELs is slow, to say the least. For example, OSHA’s PEL on hexavalent chromium was established in 1971, based on a recommendation the American National Standards Institute made 30 years earlier. Decades later, following petitions, lawsuits and a court order, OSHA updated the PEL, but the 2006 update was at a level 5 times weaker than the limit NIOSH recommended in the late 1970s. The current NIOSH recommendation (established in 2008) is 25 times stronger than the OSHA standard. “We can’t wait any longer,” said Aaron Trippler, AIHA’s government affairs director. “We must update the PELs.”

Updating the outdated PELs

PELs typically are given as an 8-hour time-weighted average, which is the maximum level in which an employee can be exposed to a particular substance averaged over an 8-hour work shift. A majority of the current PELs are based on threshold limit values established more than 40 years ago by the American Conference of Governmental Industrial Hygienists in Cincinnati.

Several other organizations have developed similar, noncompulsory limits throughout the years. AIHA has developed workplace environmental exposure levels, and NIOSH provides recommended exposure limits that OSHA considers in its development of PELs. “We provide recommended standards to OSHA they can use as a basis for developing rules and recommendations,” said Paul Schulte, director of NIOSH’s Education and Information Division, which is in charge of REL development.

NIOSH has close to 700 RELs and is able to evaluate them, even with the institute’s limited resources. Schulte said although the process for issuing new RELs is slow – the agency comes out with a new REL for a single substance every year or two on average – it is much faster than OSHA’s process. “OSHA has many more things to address, and their process is more involved,” he said. As any OSHA observer can attest, it takes a very long time for the agency to issue or update a standard, and PELs are no exception. OSHA officials have listed several times in public comments the numerous legal and regulatory hurdles the agency must go through to promulgate a standard, including comment periods and burden-of-proof requirements.

In the late 1980s, OSHA tried to update or create hundreds of PELs en masse by simply adopting RELs and updated threshold limit values. Its final rule on the proposal wound up in the courts, where the 11th Circuit Court of Appeals vacated it and returned PELs to their 1970 levels.

According to the court, OSHA failed to describe why existing exposure limits presented a significant risk and how the new standards would eliminate or lessen that risk. The agency also failed to meet its burden of establishing whether or not the new PELs were economically or technologically feasible. In essence, the court barred OSHA from updating PELs en masse and said the agency instead must make the case for each PEL. This can result in a time-consuming process.

“OSHA has the authority” to update PELs, Trippler said. “The problem is that they have to do it individually.” The agency made a couple of other attempts at updating or establishing PELs, but none were as bold as the one in the late ’80s. One attempt focused on 20 high-priority items. The stumbling block, according to Adam Finkel, former director of health standards programs for OSHA, was that the agency lacked the appropriate people to look into the economics of the new PELs. Even if that effort had succeeded, it still would have affected only 20 PELs out of hundreds needing to be updated, said Finkel, who also is on the Public Employees for Environmental Responsibility’s board of directors.

Another attempt to speed up the process involved getting stakeholders together – such as industry and union representatives – to establish ground rules on how the scientific and economic analysis would be conducted on the PELs. “The idea was not to negotiate each PEL, but sort of negotiate the process,” Finkel said. That, too, fell apart – this time because the groups did not want to participate. “Industry has been supportive of the idea of putting all the science together and developing PELs, and, like the unions, when it really comes down to coming to sacrifice anything, they have not been there,” Finkel said.

The ‘H’ in OSHA

Stakeholder attempts to address the PEL issue in the early 2000s likewise failed, in part, because of OSHA’s lack of participation in those efforts. During a recent public hearing with key OSHA officials, some participants called on the agency to lead the way in updating the PEL system.

“Previous efforts I think have failed, at least in part, because OSHA failed to play much of a proactive role,” Frank White of Washington-based ORC Worldwide said during the “OSHA Listens” public hearing in March. “We encourage OSHA to take a leadership role in this regard.” (For more on the hearing, see “OSHA Listens” on p. 32.)

To some, OSHA has been unwilling to tackle this issue. Finkel asserts that the vast majority of OSHA’s efforts are focused on safety-related activities, with very little – perhaps only 5 percent – dedicated to health. “I think health is 90 percent of the problem if you just look at the well-documented estimates of tens of thousands of people who die prematurely from long-term exposure in the workplace,” he said said.

If that is the case, it would seem OSHA’s prioritization is off. And figures from some groups seem to confirm the agency’s efforts on health standards and chemical hazards leave something to be desired. “In recent years, regulations for chemical hazards have ground to a halt,” the AFL-CIO said in its 2009 annual “Death on the Job” report. According to the federation, only 29 comprehensive health standards are from OSHA, most of which were issued in the first two decades of the Occupational Safety and Health Act’s existence. Since 1998, the only OSHA health standard was the court-ordered hex chrome standard in 2006, according to PEER.

This has led organizations such as the AFL-CIO and PEER to campaign for OSHA to change its priorities and focus on the PEL problem. “The short version is to put the ‘H’ back in OSHA,” Ruch said. Trippler said AIHA is forming an internal workgroup to discuss the issue, including what options are available and any alternative approaches that should be considered in addressing the PEL problem. Once that group forms a consensus, AIHA will invite stakeholders – which Trippler hopes will include OSHA – to make recommendations and reach an agreement about how to proceed. OSHA disagrees with the notion that it fails to put an emphasis on chemical or health-related hazards. Responding to those assertions, an agency spokesperson said the resources OSHA devotes to chemical hazards are “comparable to those used to promulgate safety standards.” That being said, OSHA as of late has been reaching out to stakeholders to find better ways to more efficiently address workplace chemical exposures.

Solutions

One way OSHA reached out was the “OSHA Listens” public meeting in which the agency invited stakeholders to comment on whether or not PELs should be a priority. The agency also asked for suggestions on updating PELs, or other ways workplace chemical exposures could be controlled.

In response, several hearing attendees offered their own advice on the best way OSHA could improve its PEL and chemical hazard process. Matthew Shudtz, a policy analyst for the Washington-based Center for Progressive Reform, suggested streamlining rulemaking by using peer-reviewed health assessment by other agencies such as NIOSH to show risks to workers, which could allow OSHA to avoid writing hundreds of pages of risk analyses.

The agency also could expand the General Duty Clause to protect workers from chemicals that have no PELs, Shudtz said. “Significant risks have been discovered, and recommended occupational exposure limits exist,” he said. “OSHA could use these levels as a starting point for establishing a case that certain worksites have known hazards that are likely to cause death or serious physical injury.”

Noting that promulgating new standards sometimes takes decades, Trippler suggested at the hearing that perhaps individual standards were no longer possible. “Maybe you need to take a look at a broader, generic General Duty Clause; a generic exposure standard; or maybe just risk assessment in general,” he said.

While stressing some chemicals and hazards such as silica may need to be specifically addressed by OSHA, John Morawetz from the International Chemical Workers Union in Akron, OH, likewise suggested the agency pursue a broad approach – one that puts the responsibility on employers.

“Mandating that facilities with their workforce have a plan to identify and address their own problems will likely find many emergent problems and force these significant new hazards to be addressed,” Morawetz said. Such an approach, he said, could be process-driven instead of chemical-specific.

Although he did not testify at the hearing, Finkel echoed Morawetz’s suggestion of process-driven standards. Instead of tackling one chemical at a time, OSHA could divide everything up into industrial processes and establish standards for those processes. For example, a dry-cleaning process standard could mandate the use of machines that ensure workers are never exposed to cleaning chemicals, regardless of what those chemicals are. “You wouldn’t have to take measurements because you know the equipment achieves a certain level of risk reduction that’s more than enough to be protected,” Finkel said.

Potential for change

When asked about the various options that could be considered in updating PELs, including process standards, an OSHA spokesperson said the agency remained open. “OSHA has not ruled out any approach that would enable the agency to effectively address workplace chemical exposures more effectively than traditional substance-by-substance rulemaking,” he said.

With the appointment of David Michaels as OSHA administrator, people hoping the agency will address the PEL issue have expressed optimism. An epidemiologist by trade, Michaels has supported OSHA issuing or updating PELs for hot-button chemicals such as diacetyl and beryllium. “I’m cautiously optimistic,” Finkel said. “He’s got a tremendous challenge ahead of him.”

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)