Cut-resistance standards

Can you explain the misconception of EN vs. ASTM cut standards?

Responding is Amy Taft, product manager – hand protection, Protective Industrial Products Inc., Latham, NY.

Although we try to make it sound simple, there is an immense misunderstanding concerning the EN388 and the ASTM F1790-05 cut tests. Different testing methods, ratings and standards can seem overwhelming when trying to select the correct product. Both tests provide the user with a cut rating that is supposed to help guide them while making a decision on what type of cut product to use, but that is the only thing they have in common, as the two tests are not interchangeable. When discussing cut-resistant performance levels, you need to confirm which standard is being used.

ASTM

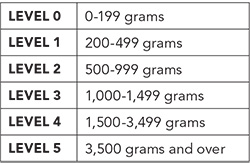

ASTM F1790-05 is the standard most frequently used in the United States as a way to measure the cut resistance of the material when exposed to a cutting edge under specific loads. Testing can be performed in house or by a third-party laboratory by using a TDM-100 or CPP tester. The ASTM F1790-05 uses a 4-inch straight-edge blade. The sharpness of the blade is calibrated into the testing program in order to provide the most accurate information. Each time the blade makes a complete cycle or cuts through the sample, it must be replaced with a new blade to ensure accuracy. The sample is cut five times each at three different loads, and the data is used to determine the required load (grams) to cut through the sample. The gram weight information then is applied to the ANSI/ISEA 105 table at left.

ASTM F1790-05 is the standard most frequently used in the United States as a way to measure the cut resistance of the material when exposed to a cutting edge under specific loads. Testing can be performed in house or by a third-party laboratory by using a TDM-100 or CPP tester. The ASTM F1790-05 uses a 4-inch straight-edge blade. The sharpness of the blade is calibrated into the testing program in order to provide the most accurate information. Each time the blade makes a complete cycle or cuts through the sample, it must be replaced with a new blade to ensure accuracy. The sample is cut five times each at three different loads, and the data is used to determine the required load (grams) to cut through the sample. The gram weight information then is applied to the ANSI/ISEA 105 table at left.

EN388

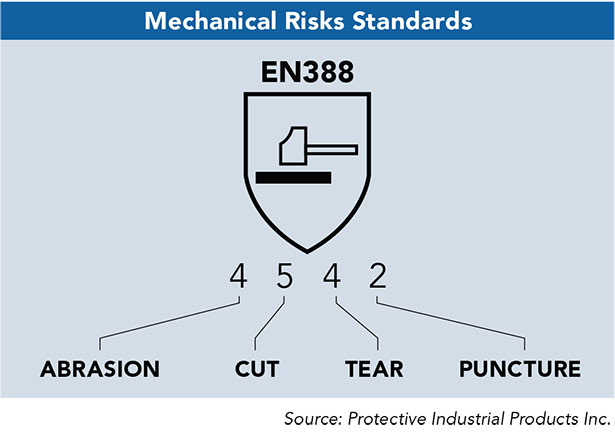

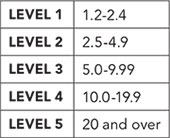

EN388 is the protection against mechanical hazards standard that is used in the European Union countries as well as Asia, South America and Australia. EN388 is expressed by a pictogram followed by four numbers (performance levels), each representing test performance against a specific hazard. There are four hazards – abrasion, cut, tear and puncture – which are always listed in this order.

EN388 performance levels

Which test method is better?

Neither is indicative of actual performance as all applications are different. Cut protection is a combination of many factors, not just the fiber or fabric used in the construction of the glove or the number achieved from a cut score.

Fit, grip, temperature and coatings also play a significant role in selecting a proper glove for the application. Don’t rely solely on scores as a result of tests performed in a laboratory.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.