Regional spotlight

Much ground to cover

OSHA Region 6 has both troubled refineries and exemplary worksites  By Ashley Johnson, associate editor

By Ashley Johnson, associate editor

The 2005 explosion at BP’s Texas City refinery was a major event not only for the industry, but for OSHA Region 6.

The agency’s initial investigation led to a then-record $21 million penalty, and a follow-up inspection revealed uncorrected hazards, prompting citations totaling $87 million. OSHA officials also worked out an agreement with BP to ensure safety at the refinery, according to Jeff Lewis, who served as acting deputy regional administrator before former Region 3 Administrator John Hermanson took over in Texas in May.

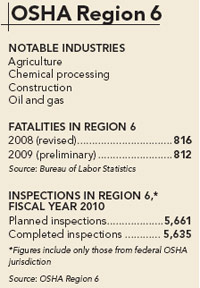

Refineries continue to be a major focus for Region 6, which encompasses Texas, Arkansas, Louisiana, Oklahoma and New Mexico (a State Plan state).

As part of a National Emphasis Program, Region 6 recently inspected 40 refineries. “[In] just about every single one of them we found some level of deficiency related to process safety management,” Lewis said.

The number of citations varied from a handful to considerable, with some refineries receiving penalties in excess of $100,000.

Yet Region 6 also is home to 500 worksites in OSHA’s Voluntary Protection Programs – the most of any region, Lewis said. He noted that more than 100 VPP sites are located within the boundaries of the Houston South and Baton Rouge area offices.

Oil and gas challenges

Last year, Region 6 faced the challenges brought about by the Deepwater Horizon oil rig explosion and oil spill off the coast of Louisiana. OSHA’s efforts to protect response workers relied on the same interagency coordination that was central to its Hurricane Katrina response in 2005.

“We worked side by side with other federal agencies and the state partners in Louisiana to provide safety and health services, education, and technical assistance to the myriad of response workers that came to the state of Louisiana to respond to those two tragic events,” Lewis said.

A constant difficulty for Region 6 is monitoring safety at oil and gas sites. Depending on the project, workers may be at a location for only a couple of days or weeks. “Being able to identify those locations is somewhat of a challenge for us because there’s not really a good system set up to know where a company will be working at,” Lewis said.

But Region 6 is making inroads with the industry. Last year, OSHA co-hosted an oil and gas safety conference in Dallas. Lewis said the event allowed agency representatives and the 1,200 attendees “to interface, interact and discuss safety and health issues, best practices, sharing information, sharing knowledge – all in the effort of providing a safe workplace for those men and women who work in the oil patch.”

Another industry of concern is construction. Roughly half of the region’s 16 Local Emphasis Programs target construction hazards. Other topics include heat-related illnesses, grain handling and fabricated metal.

Trust issues

The diverse workforce in Texas can present language and cultural barriers. Some immigrants view government representatives with suspicion, which complicates OSHA’s outreach efforts.

“Our mission is to be there to provide assistance and a service, and they may not always trust us when we’re trying to talk to them,” Lewis said.

To target Latino workers, Region 6 participated in the National Action Summit for Latino Worker Health and Safety, which took place in Houston last year.

On a broader level, Region 6 reaches out to employers and workers through compliance assistance specialists and OSHA Training Institute Education Centers at the University of Texas at Arlington and Texas Engineering Extension Service.

Lewis said Region 6 has “a great relationship” with the state-run program in New Mexico, known as the Occupational Health and Safety Bureau. He praised the bureau for establishing programs to protect late-night retail workers and lower lead exposure in auto shops that repair radiators.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)