MSHA cautions miners about working near oil and gas wells

Arlington, VA — The Mine Safety and Health Administration is reminding miners working near oil and gas wells to remain aware that “an inadvertent intersection with one of these wells” could be hazardous.

MSHA notes that thousands of wells in the United States penetrate coal seams under active mining operations. At mines that inadvertently intersect with active gas wells, methane gas may engulf the mining section. Inactive wells where gas reservoirs are depleted may present similar hazards if pressurized fluids or gases are present.

Additionally, the agency has reported injuries near active and inactive wells after material is forcibly injected into the mine, or the mine section becomes flooded with water.

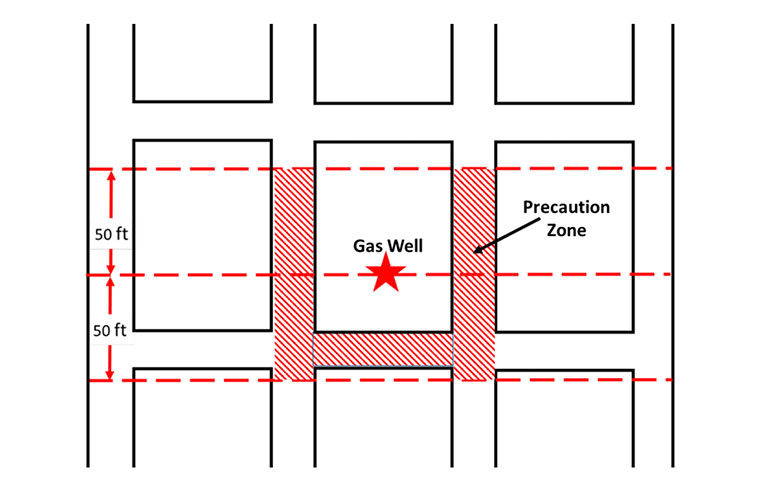

Under Title 30 CFR Part 75.1700, coal mine operators are required to take reasonable measures to locate oil and gas wells that may penetrate coalbeds or other underground areas of a mine. Operators must maintain a coal barrier of at least 300 feet in diameter around wells, which translates to a 150-foot “setback distance” – the space between a well and the closest point of development mining.

MSHA recommends establishing setback distances large enough to “mitigate risks associated with the cumulative impact” of four factors:

Well deviation: The horizontal distance between the surface location of the well and where it penetrates the coal seam.

Surveying error: The mine surveyor can calculate the potential location error on the mine map from the closure ratio.

Mining error: The setback distance should consider errors that occur as a result of mining off-sights stemming from inadequate survey control at the face, regardless of the depth of cover.

Pillar rib weathering and peak stress avoidance setback: Addresses risks associated with a well penetrating the zone of the pillar where weathering of the rib or high pillar deformations occur.

“When a mine operator develops entries or crosscuts near a well, an appropriate setback distance serves to protect miners from risks associated with inadvertently intersecting the well,” Gregory Rumbaugh, supervisory engineer at the Department of Labor, and Christopher Mark, principal roof control specialist at MSHA, write in a recently published white paper. “The mine operator should design the protective pillar to maintain stability and to account for setback errors inherent to surveying, mining practices and well deviations.”

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)