The right way to wear disposable earplugs

A step-by-step guide

Hearing loss, which typically progresses slowly over time, is the third most common chronic physical condition among U.S. adults, according to NIOSH.

Each year, 22 million U.S. workers are exposed to hazardous noise on the job. Yet, the agency reports, more than half of these workers say they don’t wear hearing protection.

“It’s so important for workers to wear hearing protection throughout the day,” said Jeffrey Birkner, chair of the International Safety Equipment Association’s Hearing Protection Committee.

Workers in many industries use disposable earplugs. But are they inserting them the right way? The process is seemingly simple but can be done incorrectly – leaving workers with inadequate protection from noise.

Below, Birkner, who’s also vice president of technical services at hearing protection manufacturer Moldex-Metric, and William Murphy, a health physicist on the NIOSH noise and bioacoustics team, offer step-by-step instructions on how to properly insert and wear earplugs.

Here’s how to do it

Let’s roll

The first step to prepare a foam earplug for insertion? Using clean hands, roll it between your fingers.

“Just roll until it’s uncreased and at the smallest diameter possible,” said Jeffrey Birkner, chair of the International Safety Equipment Association’s Hearing Protection Committee.

This compresses the earplug for easier insertion.

“You don’t want to just squish it in one direction and then squish it in another direction,” said William Murphy, a health physicist on NIOSH’s noise and bioacoustics team.

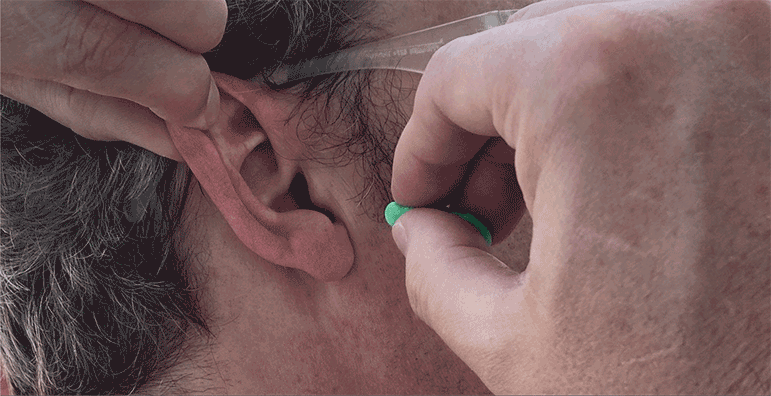

Pull your ear

To insert the earplug, reach behind your head with the opposite hand and grab the outer part of the upper ear and pull.

“Pull it up and back,” Murphy said. “That straightens out the ear canal.”

Insert and hold

The rolled earplug can now be inserted. NIOSH recommends holding the earplug in place after insertion.

“The foam will expand to fill the ear canal in most people,” Murphy said. “As the foam expands and makes contact with the ear canal walls, then you can release it.”

Check the fit

A look in a mirror or at a cellphone photo can help ensure your earplugs fit properly.

One giveaway that they don’t is “if they’re sitting outside your ear,” Birkner said. “If you’re hearing noises to the same level as without an earplug, that’s telling you that it’s not fitting properly.”

Sounds should be muffled, NIOSH says. If they aren’t, take out the earplug and try reinserting.

Murphy recommends a “tug test,” which involves grabbing the earplug and slightly tugging it to see if it will come out of your ear easily.

Photos: Jennifer Yario

Find the fit that’s just right

For workers who may have larger or smaller ear canals, identifying the right earplugs may mean seeking out various products and some trial and error.

“You can look for various sizes,” Birkner said. “Try to choose the one that will work. Don’t settle for, ‘It’s pretty close.’”

Murphy noted that employers can have workers fitted for customized earplugs that fit their particular needs.

Know when it’s time to toss

Although manufacturers of foam earplugs often recommend disposal after a single use, “the reality is that people will use them more than once,” Murphy said.

Earplugs that are dirty or contain material from your workplace – such as dust, grease or metal shavings – should be disposed of immediately. “You don’t want to be putting that material into your ear canal,” he said. “It’s a disposable product. It’s meant to be thrown away.” Earplugs that show cracking, dirt or wear also should be disposed of.

“You don’t want to use them to the extent that they’re falling apart,” Birkner said.

Lead by example

Leaders should model good hearing protection behaviors.

“If the foreman, supervisor or job boss is wearing their protection,” Murphy said, “that communicates to the workers that protection is important. Set an example for your workers.”

Birkner encourages employers to understand their responsibilities when it comes to protecting employees.

“If they’re over 85 decibels in a time-weighted average, they need to institute a comprehensive hearing conservation program in accordance with OSHA 1910.95,” he said.

Examples of noise that is 85 decibels or above include a power lawnmower, a forklift, a bulldozer, an impact wrench and hammering in a nail.

“It’s just good practice at 85 decibels and above to wear earplugs,” Birkner said.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)