7 tips for safe use of ladders

Ladders are common at workplaces across the country. So common, according to Ryan Moss, president of the American Ladder Institute, that safety can get overlooked.

“I think it’s important for us to realize that ladders are safety equipment, not just a throwaway tool,” Moss said.

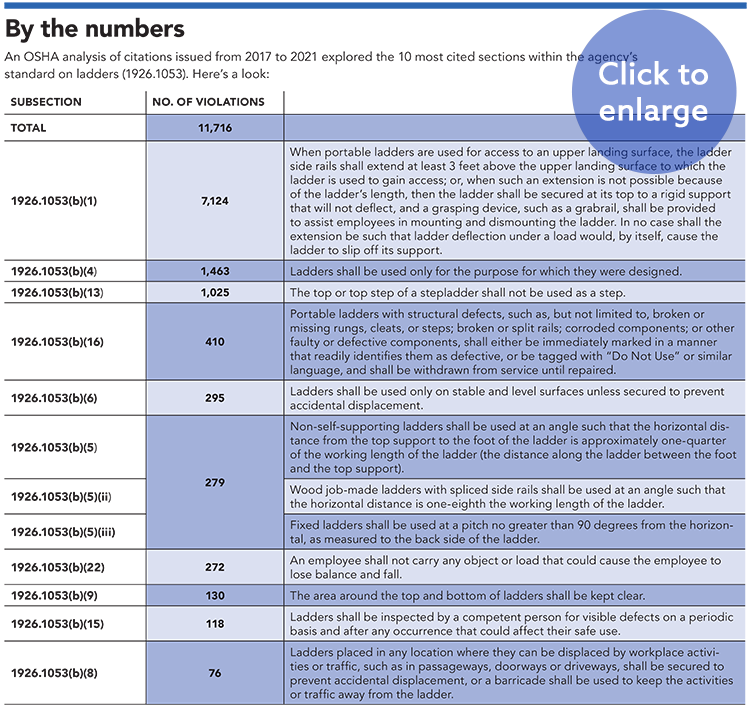

The numbers back him up. From 2017 to 2021, ladder-related incidents accounted for more than 800 deaths and 27,000-plus nonfatal injuries resulting in days away from work, according to a recent OSHA analysis of Bureau of Labor Statistics data.

“When you look at those numbers, they are significant,” said Erin Gilmore, director of OSHA’s Office of Construction Services, “and it’s an example of why ladder safety is so important. It contributes to falls when ladders are used unsafely, and those falls will have impacts on workers’ lives when they are injured or killed.”

Here are seven tips for reducing the risk of ladder-related incidents and injuries.

Pick the right ladder

According to ALI Vice President Mike Van Bree, “One of the big issues is users not selecting the right ladder for the task” – whether out of convenience or availability.

Choose the right ladder for the job and make sure you receive training on its proper use. Failure to do so often leads to ladder users overreaching, climbing too high or getting into an awkward position.

“It’s just a matter of looking and seeing what is the job, and then asking, ‘What size ladder do I need to do the job?’” said Richard Fairfax, former deputy assistant director at OSHA and currently a principal consultant for NSC Networks – part of the Workplace Area at the National Safety Council. “And most people, they go grab a ladder from a stack of ladders and they set it up. And if it’s the wrong size, they’re going to try to make do rather than fix it.”

Inspect before use

Section (b)(15) of OSHA’s standard on ladders – 1926.1053 – states, “Ladders shall be inspected by a competent person for visible defects on a periodic basis and after any occurrence that could affect their safe use.”

During an inspection, look for loose steps, rungs, nails, screws and bolts; broken or damaged parts; and compromised warning labels. Also, make sure climbing and gripping surfaces are free of debris and slippery substances.

“Workers will typically just use ladders” without inspecting them, said Damon Bonneau, safety and occupational health specialist in OSHA’s Office of Construction Services. “But a competent person needs to inspect the ladder and make sure that the ladder is being used in a safe manner.”

Fairfax added that workers who spot a defective ladder should clearly tag the equipment and make sure it’s taken out of service.

Go (3 feet) above and beyond

An agency analysis of OSHA Information System data from 2017 to 2021 found that the most cited subsection of the standard on ladders was (b)(1), which requires that side rails of portable ladders extend 3 feet above the surface being accessed.

Not doing so can create preventable hazards during access and egress. For instance, standing on the three top rungs of a straight, single or extension ladder – a practice OSHA prohibits.

“A lot of that is due to the height not necessarily being taken into account appropriately beforehand and the ladder just simply isn’t long enough” to access the work surface with the 3-foot clearance required, Gilmore said. “But that’s what they have, so that’s what is used.”

Maintain three points of contact

Casually climbing ladders can lead to injuries – and even death.

Always maintain three points of contact when climbing, OSHA says. This means using two hands and one foot or two feet and one hand. And your body should be positioned near the middle of the step. Face the ladder when climbing.

“A lot of people are too fast going down a ladder,” Fairfax said. “They skip steps or they want to go down facing away from the ladder so they can kind of slide down the ladder if they’re wearing gloves. So it’s just important to take the same approach going down a ladder as it is climbing up the ladder.”

Whatever the case, avoid carrying tools or other items when climbing up or down a ladder, as well.

“Ladders aren’t made for carrying materials up and down on,” Fairfax said. “You have other equipment for that.”

Regarding the debate over whether workers should use rungs or rails to maintain three points of contact: OSHA regulations don’t specify. “As long as they can safely access and egress that ladder, that’s what we want them to do,” said Damon Bonneau, safety and occupational health specialist in OSHA’s Office of Construction Services.

Monitor the weather

Mulligan said foremen on jobsites can set workers up for success by understanding if and when harsh winter weather is expected. “I think about work as if we’re a soccer team or a football team or a hockey team,” Mulligan said. “Can the team be successful” in cold conditions?

Start the day by checking a mobile weather app, and continue to monitor it. Many weather apps are available at no cost.

Make a space

Have you seen a telephone technician or cable crew place cones to designate a working space?

Fairfax recommends doing the same for ladder users.

“When you’ve got a ladder up against the side of a building or are somewhere using it, it’s real important to stick up a couple of cones 3 or 4 feet away from it so people see the cones and stop.

“Because I can’t tell you the number of accidents I’ve looked at where someone’s got a ladder and it’s right near the corner of a building and someone on a forklift, or someone walking really fast or someone pushing a pallet jack or something like that, turns around the corner and they smack right into the side of the bottom of the ladder.”

Secure during transport and when storing

Oregon OSHA advises laying ladders parallel to truck beds during transport, padding points of contact with soft materials and securing the equipment to prevent movement. If transporting a ladder on a vehicle rack, make sure the rack has abrasion-resistant contact points or place and secure soft items between the ladder and rack.

Van Bree said vibration and road shock during ladder transport can cause damage quickly if the equipment isn’t secured.

“If you don’t catch that, it can lead to a problem and structurally compromise the ladder,” he said.

When storing ladders, Oregon OSHA recommends keeping them in well-ventilated areas away from threats of impact/physical damage and free from heat sources. Make sure wood and fiberglass ladders aren’t subjected to excessive humidity, moisture and sunlight.

“Where possible, storing the product inside obviously is going to be better for it,” Moss said. “Winter or summer.”

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)