Enhancing Electrical Reliability and Safety Programs

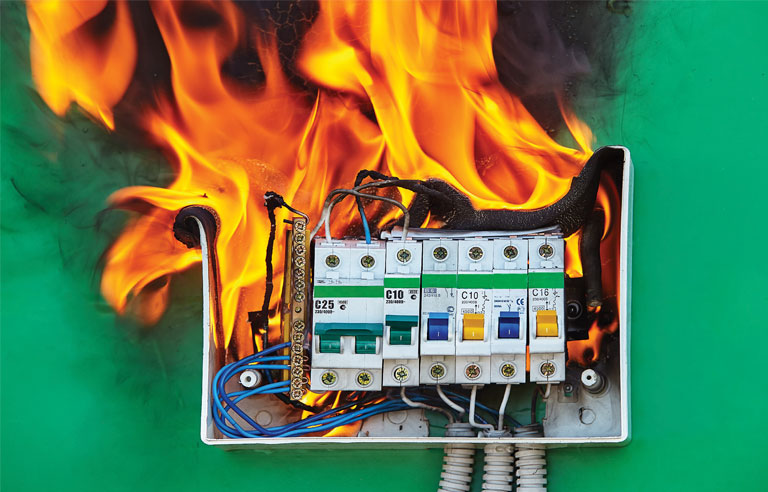

The life cycle of electrical assets typically spans 25-30 years under ideal conditions. However, many companies don’t maintain their electrical assets, which may result in reduced asset life. In addition, the inspection periods for electrical assets are often neglected and the standard operating procedures recommended by manufacturers are often overlooked. This oversight can lead to costly unscheduled downtimes, asset repairs and/or replacements. Establishing an electrical maintenance program as recommended by the Institute of Electrical and Electronics Engineers and the National Fire Protection Association can help mitigate risks of unscheduled outages and increase the life of your electrical assets.

An EMP recommendation by IEEE is to perform a thermography test with infrared inspection windows, which help to protect the operator. Thermography testing should be performed annually, or sooner based on the criticality of the electrical asset and past test results. Although thermography testing is the building block of a successfully implemented EMP, some intermittent faults may not be identified. These circumstances led to the development and introduction of industrial Internet of Things (IIoT) sensors, providing continuous monitoring of temperature, humidity and ultrasound emissions. These devices alert operator reliability and safety teams of electrical criticality risks and the actions required to mitigate such risks.

Another EMP recommendation is to perform ultrasound testing to detect partial discharge events, including loose connections, “dirty” power, delamination of windings or pest infestations. Ultrasound sensors can be standalone or embedded in the IR window, providing a fixed and repeatable test point when using ultrasound detection devices. This approach has been further enhanced by other ultrasound devices, which assess for partial discharge in transient earth voltages, UHF or high-frequency current transformers – widely used to measure fast transient current.

Developmental training has a crucial role in the implementation of an operator-driven safety and reliability program. Training such as CAT-1 ISO 18436 certification for infrared, ultrasound or TEV technologies is available, as well CAT-2 ISO 18436, CAT-3 ISO 18436 certification. This comprehensive approach ensures that teams are equipped with the necessary skills required to maximize the benefits of a well-developed, successfully implemented EMP. Additionally, asset management technologies such as E-Sentry Systems from IRISS combine data from sensors, ultrasound devices or IR cameras, streamlining the data collection and analysis process.

By implementing an EMP with thermography and ultrasound testing, and IIoT monitoring devices, a company can extend the life expectancy of its electrical equipment, as well as increase the reliability and safety of such assets and those inspecting them.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)