Cut-resistant gloves

How do I select the proper cut-resistant glove for different tasks?

Responding is Griff Hughes, president, Banom Inc., Malvern, PA.

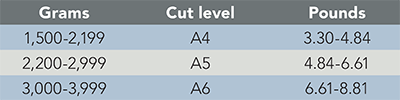

Most companies are using the ANSI/ISEA 105-2016 standard as their guideline. The standard sets cut levels based on the gram weight required to cut through a fabric swatch on a 20-millimeter pass (roughly three-quarters of an inch). The grams listed in the standard seem high in value until translated into pounds, per this chart.

These are high cut levels and represent the majority of cut-resistant gloves available. However, how many edges do you have in your facility that weigh less than 3.3 pounds (A4) or 9 pounds (A6) and will have a potential edge travel of less than 1 inch?

OSHA 1910-138(b) requires the employer to evaluate the hazard and select the proper protection to protect the employee from that hazard. Selecting a cut level may not put you in full compliance with OSHA 1910-138(b).

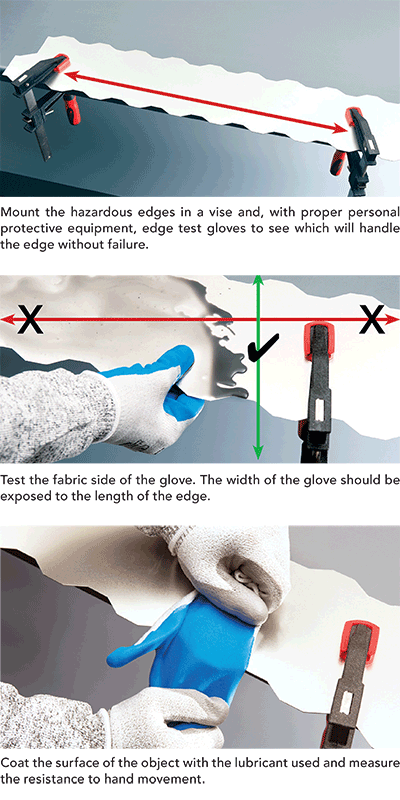

Companies that have a long history of no hand lacerations all share one thing in common: They have edge-tested gloves prior to approval for use.

This is a straightforward process. Start by touring your entire facility to see how hands are working.

- What type of objects are they gripping?

- How much dexterity is needed?

- Are there any moving parts such as turning nuts, bolts or screws with a power tool?

- Select parts and products that are being handled – from the smallest screw to the largest, heaviest edge.

Finally, wear the gloves that have passed the edge-test and evaluate them for tactile feel and dexterity by handling the small parts that you have collected. If your employees are turning screws with a power tool, you will need to use a polyurethane coating, as it was designed to help prevent “wrap-ups.” If testing a knife blade, place the glove on a flat surface and cut with a knife on a horizontal pass on the palm section of the glove. This should be repeated with a new blade for each pass.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)