The 2022 CEOs Who 'Get It'

Revathi Advaithi

CEO

Flex

San Jose, CA

Flex is the manufacturing partner of choice that helps a diverse customer base design and build products that improve the world. Through the collective strength of a global workforce across 30 countries and responsible, sustainable operations, Flex delivers technology innovation, supply chain and manufacturing solutions to diverse industries and end markets. The company has 160,000 employees at over 100 facilities in 30 countries with revenue of more than $24 billion.

Describe your personal journey to becoming a CEO who “gets it.”

Being raised by a single mother with four sisters in India played a large role in my life and influenced my leadership skills. My mother always stressed our values – the power of education, the importance of self-reliance and kindness. She encouraged us to challenge ourselves and take risks. As I reached my teenage years, I really had no idea what I wanted to do. Engineering was highly valued and felt like a good path. I landed in mechanical engineering because I liked the systematic aspect and enjoyed diving into how things work together. This in turn steered me to manufacturing.

I started my manufacturing career in America’s heartland, at Eaton, a large, diversified manufacturer, spanning many teams and divisions. After my initial stint as a shop floor supervisor, I was able to advance through different roles within the company and gain exposure to a variety of business functions and sites across the world. Irrespective of geography or location, facilities with high marks in safety typically had strong operational performance and engagement from employees, who are truly the lifeblood of any organization. While at Eaton, I began to understand that being a good leader means that you have a responsibility to take care of your people – to provide a safe, supportive environment.

Several countries and years later, I arrived at Flex as CEO in February 2019. I quickly instilled an authentic, results-driven approach to our health and safety practices. For me, it all started with our core values as a company, focused on doing the right thing always. With Flex’s size, I knew that we had to empower Flex leaders at every level to be responsible for taking care of their people and do the right thing always. And during the COVID-19 pandemic, the health and safety of our people was – and continues to be – my top priority.

The results-driven approach extends to my views toward managing the safety and well-being of our global employees. I believe that you can tell a lot about a manufacturing facility based on their safety metrics. A quick glance at those metrics and their trajectory conveys a great deal of information: first and foremost, about the extent to which the company values its employees and prioritizes their safety. Is the company doing everything it can to minimize risk and course correct for issues that impact employee safety?

Safety commitments and metrics tell you what you need to know not only about the leadership team’s efforts and attitudes toward their employees, but about their ability to ensure the facilities under their stewardship have the processes – and workplace culture – in place to optimize worker safety. Attention to detail and our workforce’s commitment to a safety-first approach are key to minimizing risk of injury.

As CEO, my primary goal will always be to ensure we are continuously identifying ways to improve employee safety. I understand that a commitment from the top that is reaffirmed at every level of the organization is the only way to build a workplace culture that truly values safety.

What is the biggest obstacle to safety at your organization, and how do you work to overcome it?

In any manufacturing environment, there is inherent risk. Big, loud machines are operating 24/7 to manufacture products for our customers across the world, and at each site, there are hundreds, if not thousands, of employees involved in this process. Machine- and equipment-related injuries are the biggest obstacle to safety for any manufacturing site.

To manage machine- and equipment-related injuries at Flex, my leadership team and I have approved significant CapEx projects related to machine safeguarding. In addition, we have provided the necessary support to drive a global program focused on safeguarding high-risk machines to eliminate serious injuries and work toward eliminating all machine-related injuries.

As part of our sustainability goals, I recently challenged the organization to be more aggressive with reducing the total case incident rate and established a target of 0.2 or less by 2025, with our philosophy of working toward an injury-free workplace. I have also supported the completion of a third-party EHS management system and organization assessment. This comprehensive assessment was completed to provide recommendations supporting our road map and drive toward the long-term TCIR targets and continued path toward an injury-free workplace.

I also oversaw our company’s response to the COVID-19 pandemic. When the pandemic hit, I stayed steadfast in my commitment to the health and safety of Flex’s 160,000 employees worldwide across 30 countries as the No. 1 priority. My leadership team and I prioritized the development of a detailed playbook to manage the situation and then replicated it across Flex’s factories around the world. Activating resources and establishing protocols to protect employees with personal protective equipment, temperature screening and physical distancing parameters happened very quickly. This enabled Flex employees to work safely and confidently as they made many of the essential products people and businesses around the world needed, including masks and ventilators.

Why is safety a core value at your organization?

The safety and well-being of our employees is Flex’s top priority. That is why I have made it a priority to set the tone and expectation that every leader is responsible to take care of their people and do the right thing always. Flex leaders are accountable to demonstrate improvements and show positive safety results along with other financial and operational KPIs regularly. I made the decision to make safety targets a part of the company goals for fiscal years 2020, 2021 and 2022 – the first time this had ever happened at Flex. Those safety targets have been cascaded into personal objectives throughout all levels of leadership across the organization. This has included a stronger focus on indicators such as reducing the TCIR and also doubling down on efforts around our culture of safety maturity assessment, which is completed at the site level, assessing 20 key processes necessary to drive a strong culture of safety.

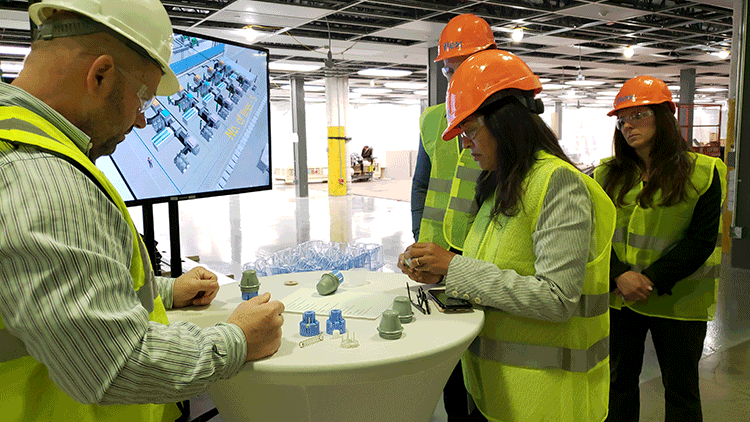

During site visits, I have led conversations in which I’ve asked purposeful safety questions, resulting in a strengthened safety-first approach throughout Flex, including starting meetings with a safety message. In addition, the company began tracking risk assessments completed globally along with actions required to mitigate significant hazards.

How do you instill a sense of safety in employees on an ongoing basis?

I believe there are two pillars that are critical for instilling a sense of safety for employees. The first is frequent communications and education. We strive to be transparent with our 160,000 employees across the world, and that requires consistent communications that reaffirm our commitment to safety as Flex’s No. 1 goal. That’s not just top-down from the CEO – we encourage any and all leaders to be open and honest in their communications around employee safety.

Communication also does not just mean offering platitudes about safety. It means providing frequent, valuable educational trainings – and refresher safety training programs – for all site managers, supervisors and employees. Overcommunicating the importance of safety is an effective way of ensuring you’ve got a safety-first culture – and that’s important to us.

The other pillar is accountability. I provide more details in my response to the next question about measurement, but we have developed the Flex Scorecard, which is our data-driven forcing mechanism for accountability.

We have taken a programmatic approach to safety, including the development and deployment of a global machine safety standard, and a program used globally to reduce machine-related incidents. We’ve created and put into place an enhanced site-level risk assessment process that ensures Flex is consistently recognizing, evaluating and controlling risk, leading to site-specific plans based on site injury and illness trends.

Finally, I am also a firm believer that culture is an important driver of safety. We strive to foster a sense of accountability and ownership within each and every employee at Flex. When employees feel empowered and valued, we have found that they are far more engaged and better equipped to ensure the safety of themselves and their co-workers.

How does your organization measure safety?

At Flex, we have 160,000 employees across 100 sites in 30 countries, making it very challenging to monitor safety compliance issues everywhere in a unified and holistic manner. At the same time, safety and compliance are essential to how we do business at Flex. We strive for safety and compliance to be a “normalized” part of every manager’s job. Our goal is to empower managers and leaders at our sites to be responsible for safety, ethics and compliance.

We want to give them latitude in terms of how they do that, but at the same time it’s important to hold our leaders accountable. That is why we developed what we call the Flex Scorecard, which is our way of assessing managers’ and leaders’ ethics, safety and compliance performance. I believe strongly that measuring those elements alongside operational experience is critical. It is not just about what you achieve, but how you achieve it.

The Flex Scorecard is a way to put hard numbers behind that accountability using data we already collected to identify hot spots, room for improvement and areas of excellence.

At Flex, we are focused on fostering a safer, more compliant and ethical culture using data – and we have a ton of data. The challenge has been in pulling it all together in a way that we can analyze effectively and take actions when needed. The good news is that most of this data is already collected somewhere.

I encourage safety and compliance leaders to focus on breaking through siloed surveys and reports and work on persuading management that it’s better to encourage integration with one another – this will demonstrate and enable a transparent view of the company’s actions. CEO buy-in is critical here, because otherwise teams would have a very hard time aggregating data from different groups, and you need to have good, reliable data for a program like this to work well.

We pull data from a number of internal and external benchmarks, including hotline reports, substantiation rates and anonymous reporting. We also consider employee engagement, culture and risk perception, and employee perception survey summaries. We take these data sets and other information from cross-functional groups such as HR and internal audits and create a graphical representation of the issues noted based on the category, level of security and conclusion. From there, we map a course of action for remediating the risks.

The data has been incredibly helpful in identifying any compliance lapses that lead to safety issues across regions and sectors. The scorecard helps us identify hot spots and, in some instances, we’ve been able to narrow these challenges to specific production lines in factories. It helps us continue to maintain compliance and safe practices while allowing us to resolve issues before they become bigger problems.

Beyond the Flex Scorecard, we are constantly measuring metrics related to safety at Flex in an effort to hold our leaders accountable in areas including incident rate; injury rate; occupational disease rate; lost time cases rate; minor, serious and fatal injuries; near misses; risk assessments; safety trainings; accident-free days; and accident costs. It’s impossible to improve what you don’t measure, and we are firmly committed to a culture of safety at Flex.

What role does off-the-job safety play in your organization’s overall safety program?

Everything we do related to supporting our employees at Flex is done for the sake of their safety and well-being. Healthy, happy employees are safer employees, which is why off-the-job safety is so important to us. We provide a wide range of programs, including wellness programs, community projects and employee assistance programs to offer support to employees – physically and emotionally.

In the early days of the pandemic, we quickly understood that the health and well-being of our employees across the globe were at stake, and we were determined to do whatever we could to keep employees, their families and their communities safe.

Flex’s mission is to make great products for customers that create value and improve peoples’ lives, working with customers across a diverse set of industries, including health care. That’s why – despite never having produced a mask – I understood that the company was in a unique position to move quickly in response to the pandemic. That meant setting up the infrastructure, the processes and the supply chain to manufacture millions of protective masks in a matter of weeks.

I leaned on our team and our global resources to ensure Flex could quickly and effectively set up 12 manufacturing lines in 10 locations across the world in order to produce the masks that would keep our employees safe. Just five weeks into the project, we had our first million masks roll off the line. We were soon able to kick the project into hyperdrive across the other sites, eventually getting production up to 1.5 million masks per week – more than enough for employees.

What have you done to support employee mental health and well-being within your organization?

As part of our sustainability goals, we are committed to ensuring 100% of our employees have access to emotional/mental health programs by 2023. We want to expand our current offerings to ensure every team member across the globe has the resources needed for their emotional well-being.

Also, in response to the pandemic, we introduced and hosted the Flex Living Well Series throughout 2020. We implemented a global webinar series for employees that covered a range of health and wellness topics during the COVID-19 health crisis. Webinars on medical advice from doctors, proper wear of PPE, mindfulness, resiliency, managing home schooling and at-home workouts were offered on demand.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)