Managing a machine safety upgrade project

We need to upgrade our machine guarding. Where do we start?

Responding is David W. Kerr, consultant, Airline Hydraulics Corp., safety division, machine and process safety assessment group, Bensalem, PA.

Being lucky isn’t good enough for machinery safety and regulatory compliance. The responsible party for safe and compliant machinery is you – the machinery owner – not the original equipment manufacturer. Only you know how your machinery is operated and maintained by your employees.

With downsizing and consolidation efforts affecting every industry, the availability of in-house expertise in machinery safety has declined. For most employers, this means selecting an external machine safety partner to help navigate the complex process of machine safety upgrades, particularly if the project involves highly automated equipment or an assembly of multiple machines.

How do I get started?

OSHA and machinery safety consensus standards require a machine safety hazard analysis to be completed using a suitable hazard analysis methodology – qualitative or quantitative. Conduct the hazard analysis in a highly collaborative manner to capture input from each impacted stakeholder. This step is critical to ensure a safe and compliant solution that won’t negatively affect production, productivity or quality requirements. If your employer doesn’t have personnel with the technical capabilities to conduct the hazard analysis, an external partner may be required. Ideally, your hazard analysis partner should be able to perform or assist with safety upgrades. If not, you’ll need to confirm whether the hazard analysis documentation is detailed and transferable to the safety upgrade solutions provider.

Look for a turnkey solution

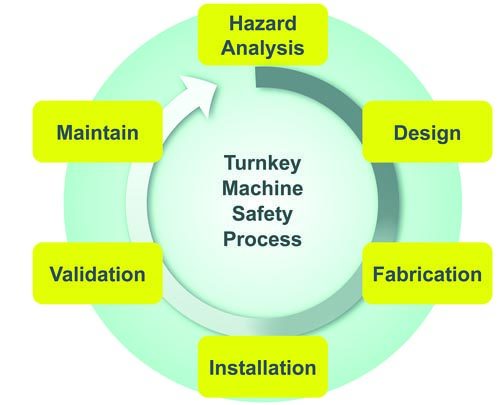

Proven strategies for implementing successful machine safety upgrade projects follow a management system framework familiar to many manufacturing and environmental, health and safety professionals. If your organization lacks the EHS and technical expertise to manage a machine safety upgrade project, seek a partner who offers fully integrated or turnkey solutions. This eliminates the need for coordination between multiple vendors, which can lead to project delays, cost overruns and incomplete solutions. The above illustration shows a turnkey machine safety process model.

Selecting an external machine safety partner

Select a partner who can accommodate changes and delays while reducing risk and achieving compliance as quickly as possible. Your partner must offer flexibility, customization, efficiency and value, and should have the expertise to evaluate and rectify any deficiencies pertaining to these key machine safety requirements:

- Suitable zero-energy state isolation devices for lockout of each hazardous energy source during maintenance and repair tasks

- Tamper-resistant barrier guarding preventing users from reaching around, under, through or over guarding

- Control-reliable safety devices, controllers and circuit wiring configurations

- Compliant and clearly labeled operating controls

- Confirmation of machine stop times for proper placement of proximity-sensing devices such as light curtains

- Validation and testing of safety-control devices, controllers and circuit configurations in accordance with ISO-13849

Because control-reliable devices and circuits play such an important role in machine safety system designs, it’s important to select a partner who has proven expertise selecting approved devices and configuring control circuits to interrupt motion and energy in a reliable and compliant manner. For legacy equipment upgrades, control-system expertise is especially critical when OEM documentation, drawings or schematics don’t exist. In these cases, the control logic of the machine may need to be reverse-engineered to locate where machine interrupting or stop controls should be integrated to achieve reliable and compliant control. Seeking the assistance of a turnkey machine safety partner having the technical requirements discussed here will help you achieve a successful machine safety upgrade project.

Editor's note: This article represents the independent views of the author and should not be construed as a National Safety Council endorsement.

Post a comment to this article

Safety+Health welcomes comments that promote respectful dialogue. Please stay on topic. Comments that contain personal attacks, profanity or abusive language – or those aggressively promoting products or services – will be removed. We reserve the right to determine which comments violate our comment policy. (Anonymous comments are welcome; merely skip the “name” field in the comment box. An email address is required but will not be included with your comment.)